Industry 4.0: The Future of Manufacturing

The manufacturing industry has come a long way since the days of the Industrial Revolution. From steam-powered machines to electricity and assembly lines, each major shift in technology has brought greater efficiency and productivity. But now, we are on the brink of a new era – Industry 4.0.

What is Industry 4.0?

Industry 4.0 is the next revolution in manufacturing. It's a time when physical, digital, and biological systems come together to create smarter and more efficient factories. By integrating technologies like robotics, artificial intelligence, the Internet of Things, and big data analytics, manufacturers can streamline their operations and make better, data-driven decisions.

Why is Industry 4.0 Important?

- Increased Efficiency and Productivity:One of the main benefits of Industry 4.0 is the increased efficiency and productivity it brings. With smart factories and the use of automation and AI, manufacturers can optimize their processes and reduce waste. They can also monitor their equipment in real-time and identify potential issues before they become major problems, reducing downtime and saving money.

- Customization Products: Another exciting development in Industry 4.0 is the ability to create customized products at scale. With 3D printing and other advanced manufacturing techniques, manufacturers can produce products that are tailored to the specific needs of customers. This means greater product variety and personalized customer experiences, while minimizing waste and reducing costs.

- New Opportunities for Workers: As with any major shift in technology, there will be winners and losers. While some traditional manufacturing jobs may be replaced by machines, Industry 4.0 also creates new opportunities for workers with specialized skills in areas such as data analytics, machine learning, and cybersecurity. The workforce of the future will need to adapt and upskill to stay competitive in a rapidly changing job market.

How Can Manufacturers Adopt Industry 4.0?

Adopting Industry 4.0 requires a significant investment in technology and infrastructure. Manufacturers will need to develop a digital strategy that outlines their goals and identifies the technologies that will best support those goals. They will also need to invest in training and development to ensure that their employees have the skills and knowledge necessary to operate and maintain the new technologies.

Manufacturers should also partner with technology providers who can help them implement Industry 4.0 solutions. This could include software vendors, systems integrators, and other experts who can help manufacturers navigate the complex landscape of digital technologies.

Finally, manufacturers should be prepared to iterate and evolve their digital strategies over time. Industry 4.0 is a rapidly evolving field, and new technologies and best practices are emerging all the time. Manufacturers who are willing to adapt and embrace change will be the most successful in the long run.

The Future is Here

Industry 4.0 is not some far-off vision of the future – it's already happening. Companies around the world are embracing these new technologies and seeing the benefits firsthand. By investing in smart factories and cutting-edge technology, they are staying ahead of the curve and driving innovation in their industries.

How to Start?

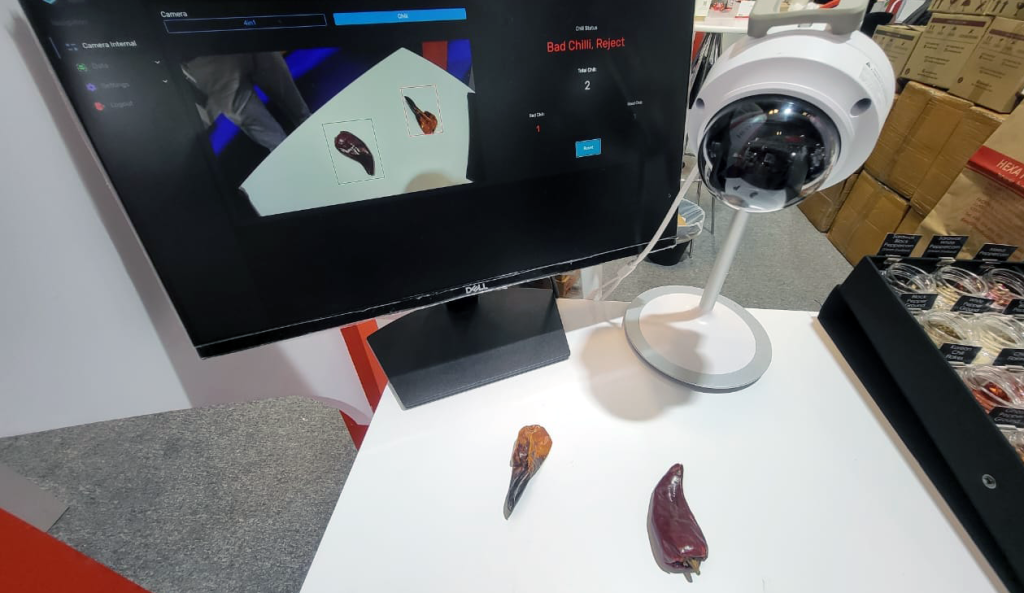

Hexa IoT is a Malaysian company with over 15 years of experience in the food manufacturing industry. Having a deep understanding of the common challenges faced by SMEs, they aim to solve these problems through the use of Artificial Intelligence of Things (AIoT) solutions. Hexa IoT current technology is fully wireless, battery-powered, and integrated with the cloud. They strive to provide SMEs with tailored solutions that are best suited to their needs. Check out more of our services at https://www.hexaiot.com.my/solution or you may contact us via email (admin@hexaiot.com.my).

In conclusion, Industry 4.0 is the next revolution in manufacturing, and it promises to bring greater efficiency, agility, and sustainability to the industry. From customized products to real-time monitoring of equipment, the possibilities are endless. As this new era unfolds, it's up to businesses and workers to adapt and seize the opportunities it presents. The future is here, and it's exciting.